Lakeview Industries provides the custom components that your business needs to improve product quality, performance and reliability. We specialize in flexible components, but can produce a wide range of parts and convert engineered material solutions to fit your needs. Our engineering team is here to assist you in developing the optimal component for your application and operational needs. We pride ourselves on our ability to add value, competitive pricing, outstanding customer support and commitment to developing innovative solutions. Get in touch today and see why Lakeview Industries is ready to serve as your reliable source for custom component manufacturing.

Custom Component Solutions for Manufacturers

We create custom component solutions that solve complex challenges for OEMs and manufacturers across industries. Our engineers use our array of material converting services to customize every solution to fit your unique application, reliably meeting project requirements and exceeding expectations. Whatever type of challenge you’re facing, we can create a solution that improves your products, enhances your operations and advances your strategic goals.

Mechanical Solutions

From bonding and fastening solutions to protective belting and complex mechanical assemblies, we deliver mechanical solutions that enhance products and boost manufacturing efficiency.

Sound and Vibration Management

We help solve noise, vibration and harshness (NVH) and buzz, squeak and rattle (BSR) issues with custom mounts and sound dampening material solutions.

Molded Solutions

Custom injection-molded rubber or plastic parts can be produced in a range of durometers to meet a wide variety of project requirements.

EMI/RFI Shielding & Thermal Management

Protect users and sensitive internal components with effective EMI/RFI shielding and thermal management solutions.

Sealing, Gasketing & Grommets

Achieve greater environmental sealing, ingress protection and prevent damage to critical components with effective sealing, gasketing and custom grommets.

Our Expertise

Lakeview Industries engineers have excessive technical, materials and industry experience that allows us to create exceptional products that optimize outcomes for our partners. We are dedicated to achieving outstanding quality in every production run and use our technical knowledge to optimize processes to produce the best parts possible. We offer consulting services, material training, rapid prototyping, design assistance and much more to help our customers elevate their businesses. For the best quality, service and cutting-edge converting services, trust our expertise and experience the value it can bring to your manufacturing operation.

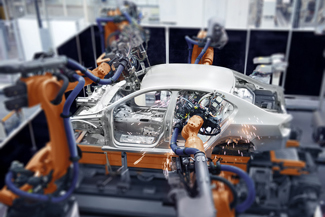

Industries We Serve

We work across industries and use our diverse experiences to drive innovation for our customers. We understand the nuances and challenges unique to each of the industries we work in, and can help devise creative solutions that drive outstanding results. Whatever industry you work in, we can create a custom component manufacturing solution to solve your greatest challenges.

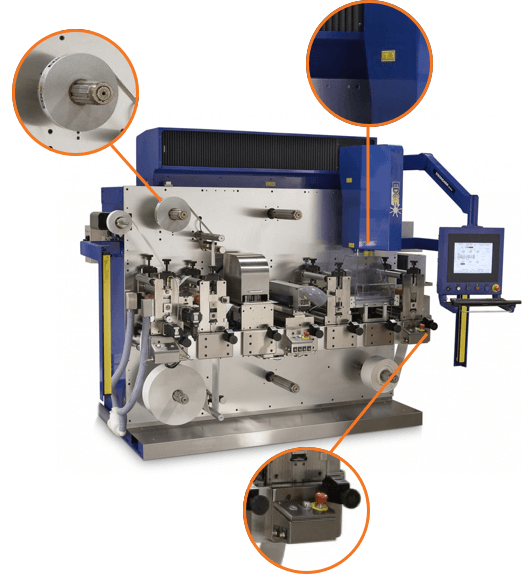

Converting Capabilities

We are a full-service material converter, offering a range of converting services and capabilities to create the custom components you need. We can maintain required tolerances on a range of materials to improve product quality and reliability on every production run. We can also combine our processes to help our manufacturing customers achieve greater efficiency and get products into market sooner. We will study your project requirements and select the optimal converting process to help you achieve your goals.

- Die Cutting

- Slitting

- Rotary Cutting

- Kiss Cutting

- Flash Cutting

- Waterjet Cutting

- Adhesive Laminating

- Skiving

- 3D Printing & Rapid Prototyping

- Assembly & Kitting

- VHB Tape

- HATS Tape

- Belting

- Sheet Rubber (EPDM, Neoprene, SBR, Silicone)

- Fabric reinforced sheet rubber (EPDM, Neoprene, SBR, Silicone)

- Foams (Polyurethane, Silicone)

- Microcellular Polyurethane

- Pressure Sensitive Adhesives (PSAs)

- Closed Cell Sponge

- Silicone

- Thermoplastic Materials

- Extrusions

Common Materials

At Lakeview Industries, our engineering team has deep experience converting a wide range of materials to specified tolerances to create custom parts with reliable quality and precision. We are a Preferred 3M™ Converter, giving us access to high-quality materials and support, enabling us to provide solutions that are ideally suited to fit our customers’ needs. We also work closely with many other major materials suppliers to further broaden the options available for our customers. We can provide guidance on materials and help your engineering team select the optimal solution for a given application.

- VHB Tape

- HATS Tape

- Belting

- Sheet Rubber (EPDM, Neoprene, SBR, Silicone)

- Fabric reinforced sheet rubber (EPDM, Neoprene, SBR, Silicone)

- Foams (Polyurethane, Silicone)

- Microcellular Polyurethane

- Pressure Sensitive Adhesives (PSAs)

- Closed Cell Sponge

- Silicone

- Thermoplastic Materials

- Extrusions